Supertech Fabrics specializes in producing and manufacturing coating and lamination fabrics for highly engineered applications.

Our state-of-the-art facility, overseen by seasoned specialists, utilizes premium grade raw materials such as glass, aramid, polymers and additives etc intricately processed with the latest technologies.

We offer a diverse material portfolio including PTFE, silicone, neoprene, vermiculite, aerogel, PVC, and PU coated and dipped fabrics, available upto 2.5 meters wide. Advanced equipment like calendars, hot-melt machines, and laminators enable us to produce multi-layered laminated textiles.

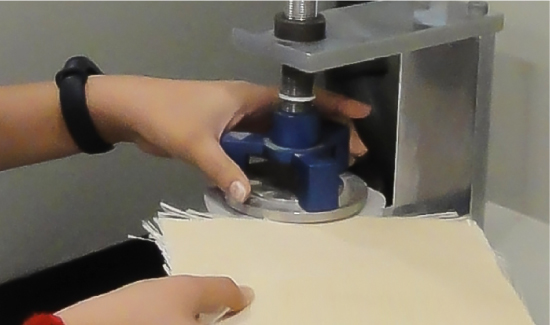

Our cutting-edge approach involves engineering materials to meet specific property requirements, then processing them through tailored equipment for optimal results. Following production, we conduct thorough quality testing on every batch to guarantee maximum product integrity and precision.

Supertech Fabrics adheres to ISO 9001, 14001, 45001, CE, and REACH certifications, affirming our commitment to quality and compliance.