FABRIC EXPANSION JOINTS

| NON METALIC EXPANSION JOINTS

Fabric Expansion Joint

They are Vital Components in industial plants that have equipment to equipment air tranfer.These are installed on duct and in piping systems that are often subject to thermal expansions,vibrations and misalignments

Expansion joints design and engineering is vital to reducing operation downtime and increasing efficiency.A well designed expansion joint leads to less uninterrupted plant performance and less maintenance down time

Product Range

Types:Circular and rectangular

Dimension:For installation in existing duct- and/or pipework the fabric expansion joints are supplied with either closed- or open ended band.

Multiple sizes available with or without steel parts

Temperature:Up to +1200°C / +2190°F

Pressure:Up to 2000 mmwg / 2.6 bar

Design of

By combining different materials and taking into consideration thermel,chemical and mechanical resistance,as well as the material fatigue properties,the design provides optimum solutions that is both technically and economically sound.

Expansion joints design and engineering is vital to reducing operation downtime and increasing efficiency.A well designed expansion joint leads to less uninterrupted plant performance and less maintenance down time

Advantages

- Low capex

- Easy to transport,easy to install

- Conpasate for movements in saveral directions simulteneously

- Minimal reactive forces

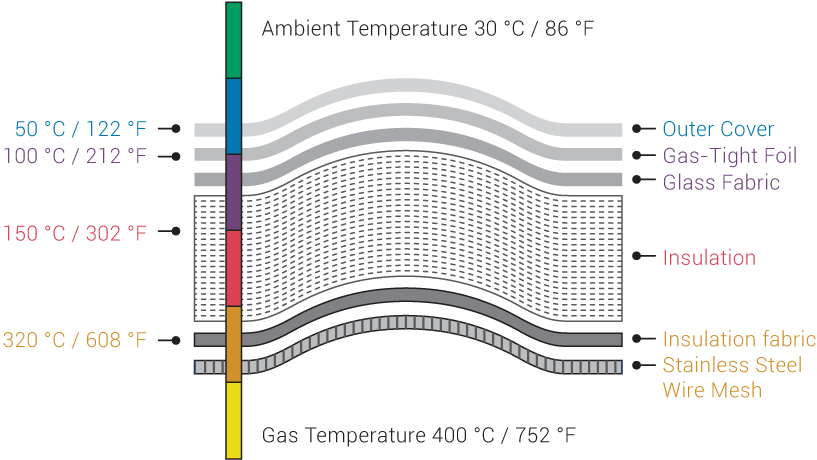

- Advanced insulation design ensures minimal heat loss

- Reduced surface temperature on the outer layer during operaion to protect site personnel

- Requires little space and little down time for installation

- Easily adapt to existing physical condition

Applications

Fabric expansion joints are foound in wide range of industries including:

- Chemical/Petro-Chemical Process Plants

- Cement Manufacturing

- Pulp and Paper Industry

- Power Stations

- Refineries

- Shipbuilding

- Steel Plant

- Suger Plant

- Gas Turbine Installation

- Incineration Food Processing

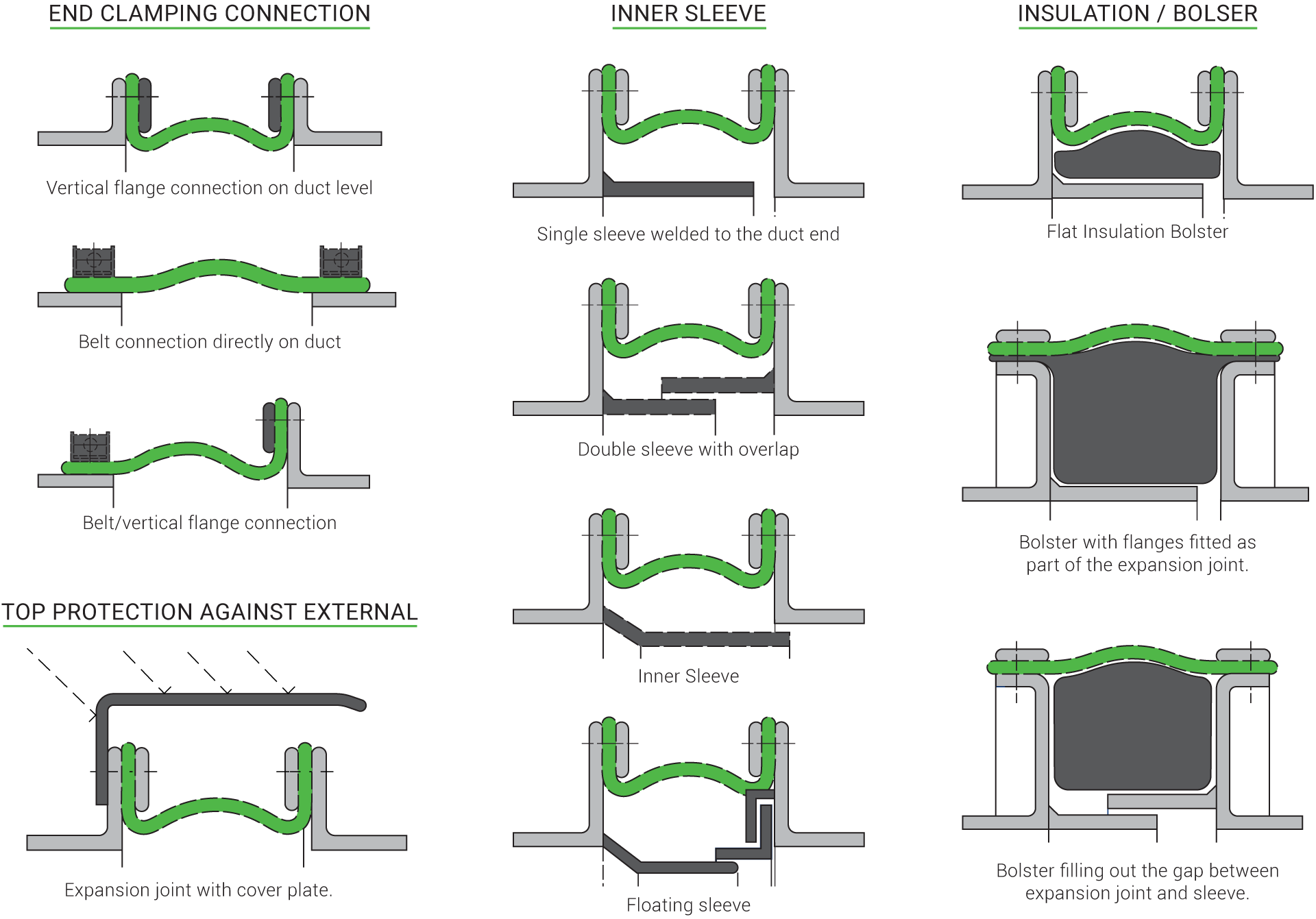

Design Configuration

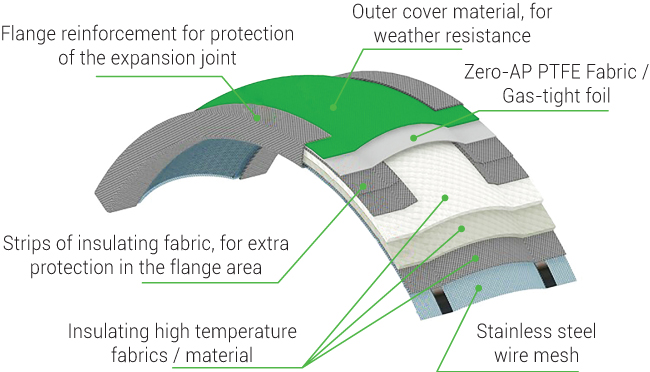

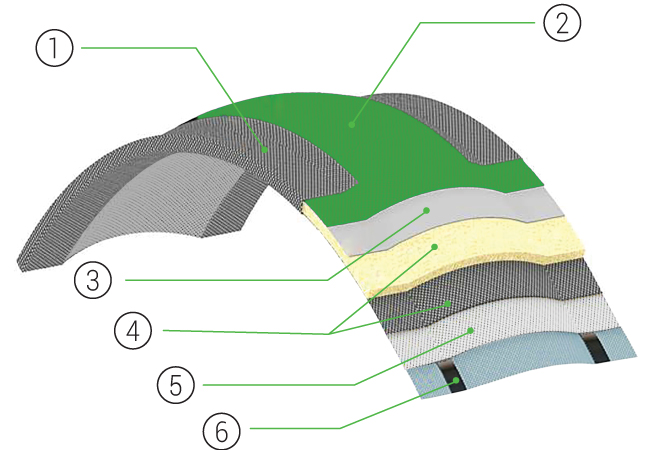

Fabric Belt Construction

Section of the optimum construction for fabric expansion joints depends on a number of factors which need to bi considered for the application,generally speaking there are no "standard" designs.Fabric expansion joints are available in many configurations with single-layer or multi-layer fabric elements.

The multiplayer expansion joint is generally mage from:

- Flange side material; avoid to abrasion

- Outer layer; to resist to whether conditions

- Sealing foil/layer; for gas tight construction

- Layers; against mechanical loads

- Inner most layer; protection against internal ensuring strong abrasion

- Mechanical reinforcement ring

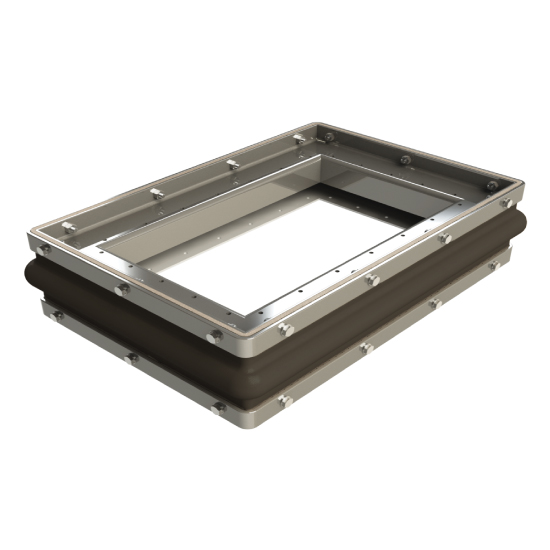

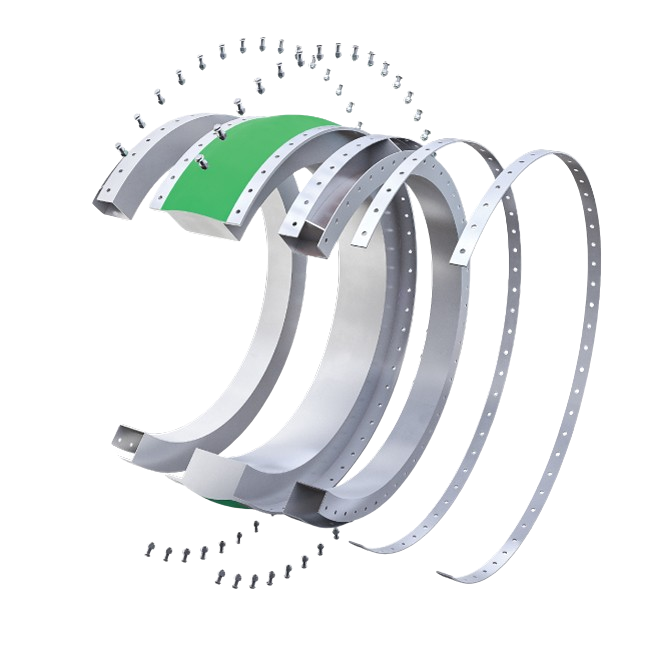

Assembly & Transportation

TEXFLEX can be supplied as a pre-assembled unit for easy installation.

The unit consists of:

- Fabric expansion joint

- Metal frames/inner sleeves

- Bolster(optional)

- Gasket(optional)

- Fasteners

Frame meterial:

- Carbon steel

- Stainless steel

- Heat resistant steel(Alloy)

Pre-assembled expansion joint units can be supplied with surface treatment that is corrosoin resistant (standard) and resistant to high temperatures.

TEXTFLEX is offered in any RAL color code foro the units.

Units can be delivered with seaworthy packing for road transportation.

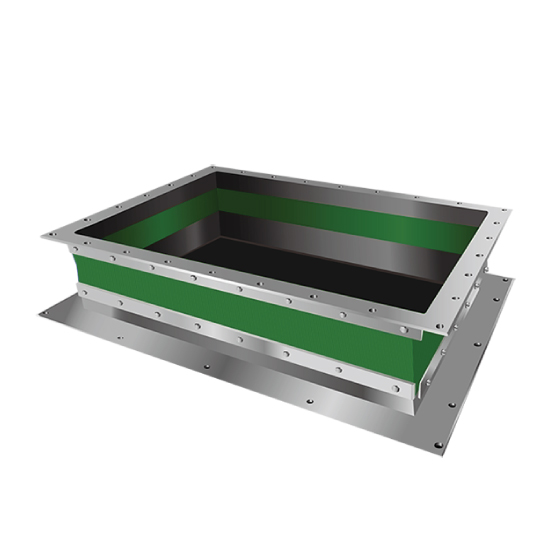

Pre-assembled unit with

expansion joint and frame

Pre-assembled unit with expansion joint,

frame/inner sleeve and

bolster

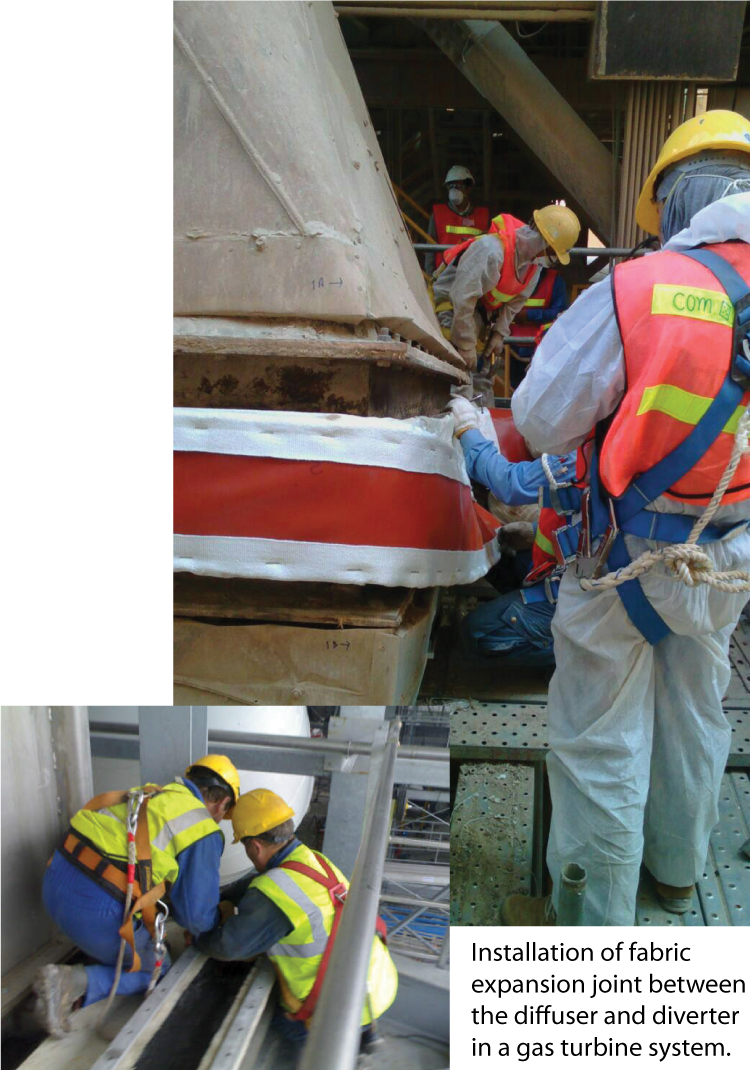

Installation

Our competence in the provision of fabric expansion joint solutions extended also to onsite services.We peovide support from the initial design,construction and installation stages and continuously thereafter throughout the service life of the equipment.We have a team of skilled installation engineers with experience in a wide range of site conditions who work in compliance with the prevailing safety regulations.

Our services for fabric expansion joints include:

- Installation

- Replacement(dismantaling and installation)

- Repair

- Assisting plant personnel in the installation/replacement work

- Inspection,i.e estimation of remaining service life(incl.report of status,evaluation and recomandations)

For such onsite work we have equipment ready and packed to ensure quick support if needed.All equipment is calibrated and we use the very latest technologies.

For more information or inquiries, we are at your service

Contact Us