FILTER BAGS AND BAGHOUSE SOLUTIONS

Science of Particle Air Separation

Solid air Filtration in high temperature heavy lies on a multifold parameter relating to system and media. The effectiveness of bag filters as a filtration mechanism for a PM2.5 as per US EPA ETV standards is what controls the emissions and can be engineered towards emission norms.

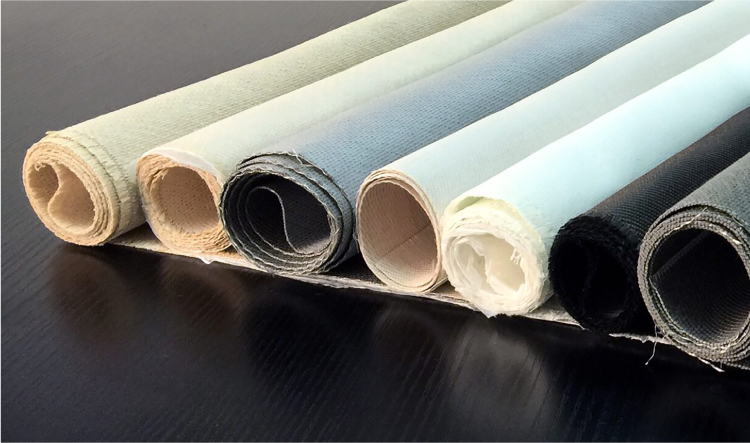

Supertech Fabrics specialises in filtration and separation media technology of using dust bags principle. Our offerings are a range of filter bags for various dust separation systems in a wide assortment of fabrics, finishes, laminated membranes and sizes along with Cage support systems.

Changes to the gas stream chemistry, moisture or hydrocarbons and/ or high temperature spikes as well as operation conditions need to be considered to maximise filter life and performance.

Filter Media Engineering

Effectiveness of Separation technology is controlled mainly by the media. Supertech Fabrics is an original materials manufacturer of such media, specialising in fiberglass and ePTFE membrane technologies.

We customise filtration fabric media to maximise filtration efficiency, dust cake release properties and durability.

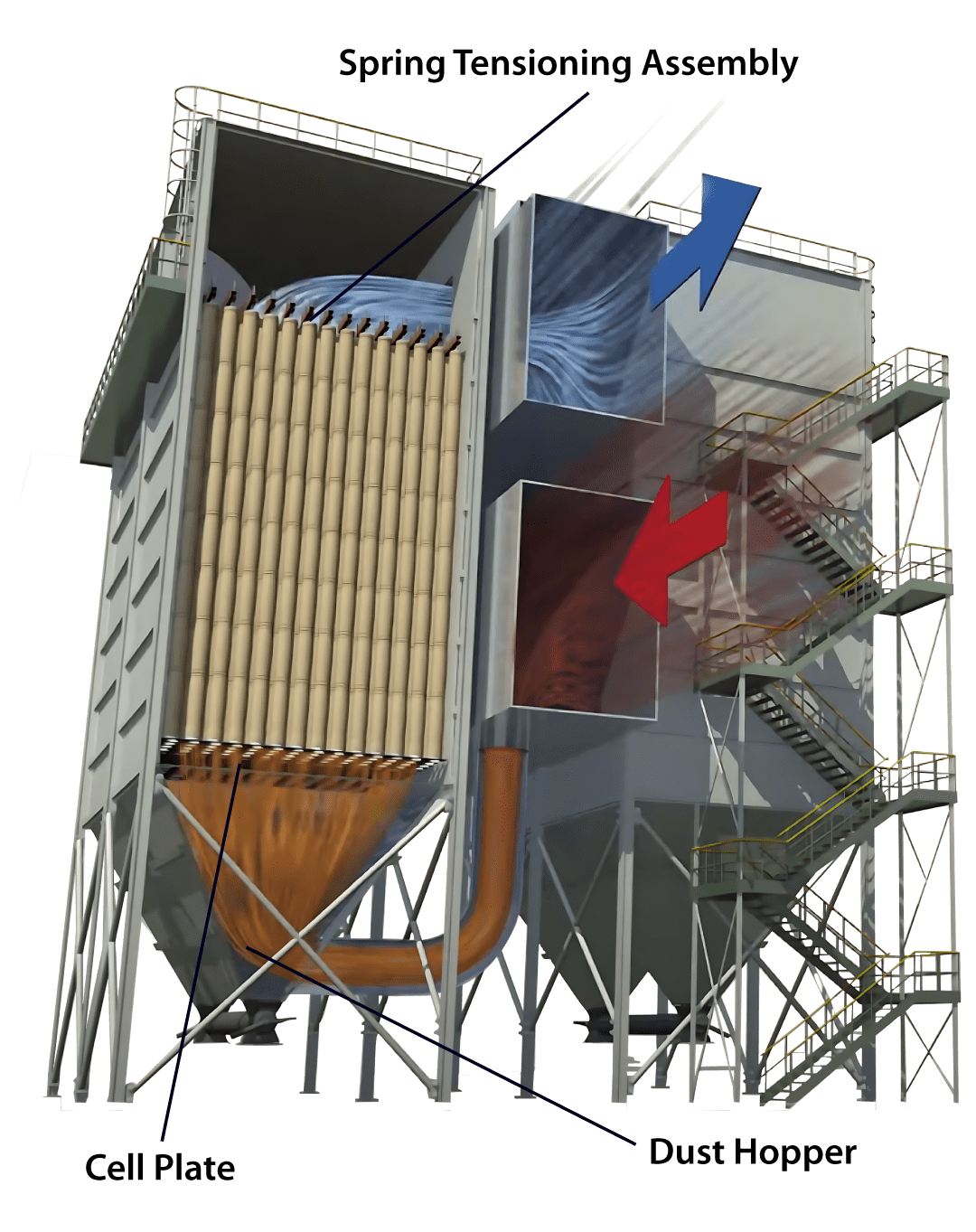

Pulse Jet System Dust Bags

Most common these days, pulse jet systems use an outside in air flow approach with a higher air to cloth ratio. Designed as a compact system, it uses cage support and pulsing technology for dust cake removal.

Changes to the gas stream chemistry, moisture or hydrocarbons and/ or high temperature spikes as well as operation conditions need to be considered to maximise filter life and performance.

Filter Media By

Woven Fabrics (Glass / PTFE / Polyester)

-

Fiberglass Pulse Jet Fabrics

- - Fiberglass PTFE Fabric

- - Fiberglass SGT Fabric

- - Fiberglass Acid Resistance Fabric

-

ePTFE Membrane Laminated Glass Fabric

- - Fiberglass PTFE Fabric

- - Fiberglass SGT Fabric

- - Fiberglass Acid Resistance Fabric

- Woven Polyester Fabric

Non-woven Fabrics

- Polypropylene

- Polyester Non-woven & Woven

- Homopolymer Acrylic

- Mixed Homopolymer Acrylic

- Aramid

- PPS (Polyphenylene Sulphide)

- P-84 Polyimide

- 100% PTFE Felt

- FMS, Nonwoven Fibreglass

- Special Microfine Fibers Added Customised Filter Media

Filter Media Finishes

- ePTFE Membrane

- PTFE Treatment

- SGT Treatment

- Acid Resistant

- Antistatic

- Glazed

- Eggshell

- Fire Retardent

Reverse Air System Dust Bags

Reverse air approach, as the same suggests, is the opposite of PJBH, where the air flows inside out. The cake formation is from inside and is removed by gravity. Unlike PJBH, there is not pulsing, the air to cloth ratio is very low, and therefore some would treat this system from a filtration stand point as more effective and simpler. Therefore it is very popular as a solution where material recovery is involved. It is more space taking though.

RABH utilises a lower GSM in both woven and non-woven, with ePTFE membrane from the inside.

Filter Media By

Woven Fabrics (Glass / PTFE / Polyester)

-

Fiberglass RABH Fabrics

- - Fiberglass PTFE Fabric

- - Fiberglass SGT Fabric

- - Fiberglass Acid Resistance Fabric

Non-woven Fabrics

- Polyester Non-woven

Filter Media Finishes

- ePTFE Membrane

- OWR Treatment

- Eggshell

- Fire Retardent

Filter Cages

Our Filter cages are manufactured by a high grade automatic welding line that keeps the joins smooth and not sharp, one of the prerequisites of sustained bag life. Manufacturing has a capacity to handle materials like Mild steel, Galvanized steel, and Stainless steel.

Cages are fabricated from

- Galvanized carbon Steel

- 304 Stainless Steel

- 316 Stainless Steel

- Mild Steel

Split Designs

- Ring to Ring Locking

- Twist Lock

- Groove Split Lock

- Slide Lock

Types of cages

- Single piece type

- Split type

- Round type

- Flat type

Types of Surface Finish

- Heat Resistance Aluminum Paint

- Heat Resistance Black Paint

- Galvanizing

- Epoxy

- Powder Coating

Cage construction consists of various diameters from 120 to 160 in wire configuration of 8, 10, 12, 14, 16, 18, 20, 22 and 24.

Controlling Critical Emmission Levels

Filtration is a 4 step process to get effective, efficient and consistent emission control with a good life cycle span.

1

ASSESSING BAG HOUSE CONDITION AND FLUE ANALYSIS

2

SELECTION OF THE RIGHT MEDIA

3

QUALITY OF PRODUCT AND FITMENT SERVICES

4

MAINTAINING BAG HOUSE PARAMETERS AND PERIODIC SERVICING

Application

CEMENT INDUSTRY

As the industry’s backbone to pollution control and material recovery, filter bags have a wide range of applications in the plant. From Raw mill, to cement mill, to coal mills. Typically a combination of both RABH and PJBH, with various flue gas conditions.

FERRO ALLOY

STEEL MILLS

ALUMINUM FURNACES

CARBON BLACK

Like cement, Carbon block industry also depends highly on filter bags and its efficiency. Typically found with both RABH and PJBH with a very fine particle size.

MSW INCINERATORS

COAL FIRED POWER PLANTS

DRYERS

BOILERS / HIGH TEMPERATURE DEDUSTING

Utility boilers in Chemical/Pharmaceutical/ textile/ paper/ polymer/ and many other industry types are utilises a vast range of fuels including solid and gas. emissions from such demanding flue gas compositions are met with filter bags.